Circular construction

Our planet's resources are being utilised more intensively today than in any previous era, although it has long been clear that they are often only available in limited quantities. The construction industry has a special role to play here. Here, it is not enough to focus on the sustainability of buildings solely in terms of energy efficiency and CO2 emissions during operation, which is where the amendment to the Building Energy Act (GEG) comes in, for example.

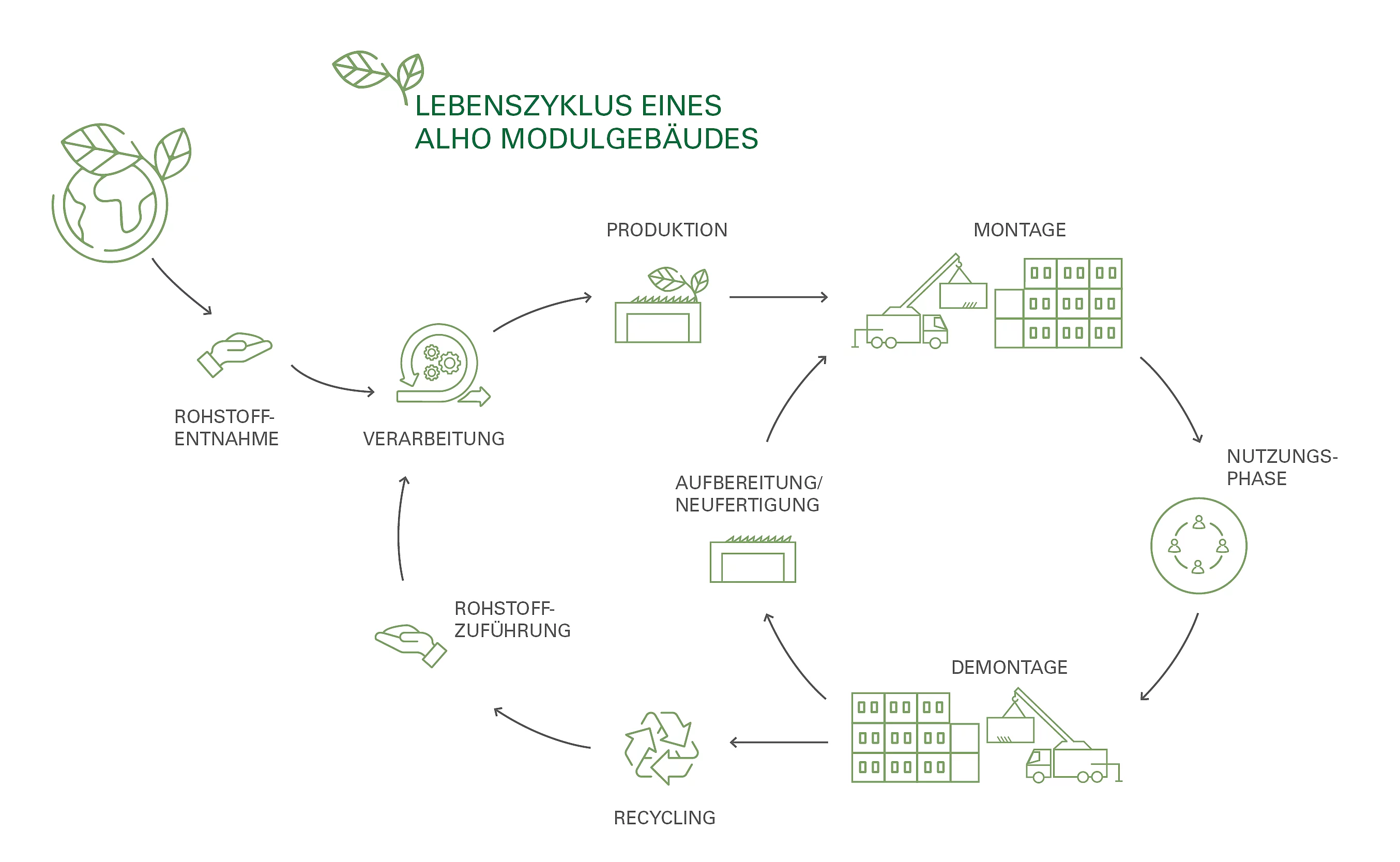

A holistic view of the entire building life cycle - from the building materials, construction, operation and remodelling through to dismantling and recycling - is necessary. This is because the production of building materials and the construction and demolition of buildings consume large amounts of energy. This is known as grey energy. The proportion of grey energy in buildings is between 40 % and 60 % and therefore accounts for roughly half of a building's energy balance over its life cycle.

Extraction of raw materials by the construction industry

The construction industry has a significant influence on the use of raw materials and therefore also on the consumption of resources worldwide. The construction industry therefore plays a key role in dealing with finite raw materials, as the potential for savings through resource efficiency is currently only being realised to a limited extent.

In particular, the production of building materials required for conventional solid construction, such as cement and concrete, requires considerable quantities of non-renewable resources. In addition to the extraction of raw materials, the production of building materials also represents a significant factor in the environmental balance of the construction industry. In terms of sustainability, resource conservation and climate protection, the construction industry will therefore have to increasingly focus on keeping existing materials in cycles and reusing them as often as possible without any loss of quality.

Urban mining and circular construction

When planning a building, demolition is not usually taken into account. The idea of building for eternity still prevails, but demolition is often a reality, consuming large amounts of energy and generally leading to a massive waste of resources. In Germany alone, for example, according to the Federal Statistical Office, around 198 million tonnes of construction and demolition waste flowed out of the construction sector in 2020, which corresponds to 55% of the total German waste volume. This is where the idea of urban mining comes into play. This involves the recovery of usable or recyclable building materials and components from buildings that were not designed and constructed in a recyclable manner. In Germany, almost 90 % of construction and demolition waste is already recycled in the sense of an anthropogenic raw material store. The problem with this, however, is that it is generally downcycled. This refers to the reuse and recycling of used components or building materials that are associated with a loss of quality - e.g. when concrete is shredded and utilised as filling material in road construction. The construction industry is therefore still a long way from a circular economy that defines itself as a self-recovering and renewing economic system that aims to maintain the highest possible quality of its materials and products in closed material cycles.

Modular steel buildings correspond to the idea of a building that is intelligently planned and designed with foresight with regard to the material cycle. They have a special feature among permanent buildings because they are "mobile properties". The modular steel construction makes it possible to dismantle buildings by breaking them down into individual modules, transporting them to another location and reassembling them there. The basic steel construction makes it possible for the buildings to be given further lives in this way.

Modular buildings thus symbolise the principle of recycling and reuse, which goes far beyond urban mining. Reuse is when a material or component is reused 1:1 in a further utilisation phase. This is the case when a modular steel building is dismantled and reassembled at another location without any changes.

As a rule, however, the principle of reutilisation applies to modular buildings. In contrast to reuse, the building is adapted to new requirements, e.g. by changing the floor plan, the technical building equipment or because it has to be adapted to new building regulations.

The basis for the ability to relocate the ALHO building system is its self-supporting steel skeleton structure with non-load-bearing walls. This makes it possible to flexibly adapt the modular buildings to changing requirements and subsequent uses by changing the floor plan. Walls can be moved or opened, and extensions and additions can be added quickly and easily. In this respect, the modular construction system is extremely flexible and very suitable for subsequent changes and conversions. This type of subsequent utilisation often comes into play when the building retains its location. The ability to repurpose is already a key feature for the sustainability of a building in the DGNB and BNB assessment.

The ALHO modular construction method provides for a three-dimensional construction of individual steel modules. These are mechanically connected to each other and can also be separated again. Due to the double-shell nature of the column, floor and ceiling construction, the building can be easily dismantled into its individual modules once the welded connections have been released. All room-related installations are pre-installed in the individual modules at the factory and integrated into the various media routes on site. As the buildings have generally been used at one location for many years before being relocated, conversion measures are often necessary for a new use, resulting in room changes or additions as well as structural upgrades due to changes in laws and standards.

These are possible either after dismantling during interim storage at a processing site or after reassembly at the new location, largely without additional intervention in the supporting structure and thus the statics. As new customer requirements usually have to be realised and current legal requirements taken into account when the building is relocated, it is virtually impossible to reuse it one-to-one in practice. However, by recycling a modular building with a high proportion of reused building materials, especially the steel structure, modular construction sets standards in terms of sustainability and resource efficiency in the construction industry.