General contractor

As an experienced general contractor, ALHO realises turnkey buildings from a single source - efficiently, on schedule and to the highest quality. We coordinate all trades, work with reliable partners on an equal footing and rely on our own in-house specialist planning. In this way, we guarantee smooth processes, transparent communication and optimum results from the initial idea to handover.

Turnkey construction

Building means coordinating a large number of different trades - this is just as true for modular construction as it is for conventional construction. The big difference: we take on this mammoth task for you in its entirety. With us, you commission a general contractor who provides a turnkey service and delivers a building realised according to your ideas at an all-inclusive price.

We integrate the various trades into our production processes just in time and organise them on site. As a total contractor, we not only take responsibility for the construction work but also for the construction planning, including preliminary planning and approval planning.

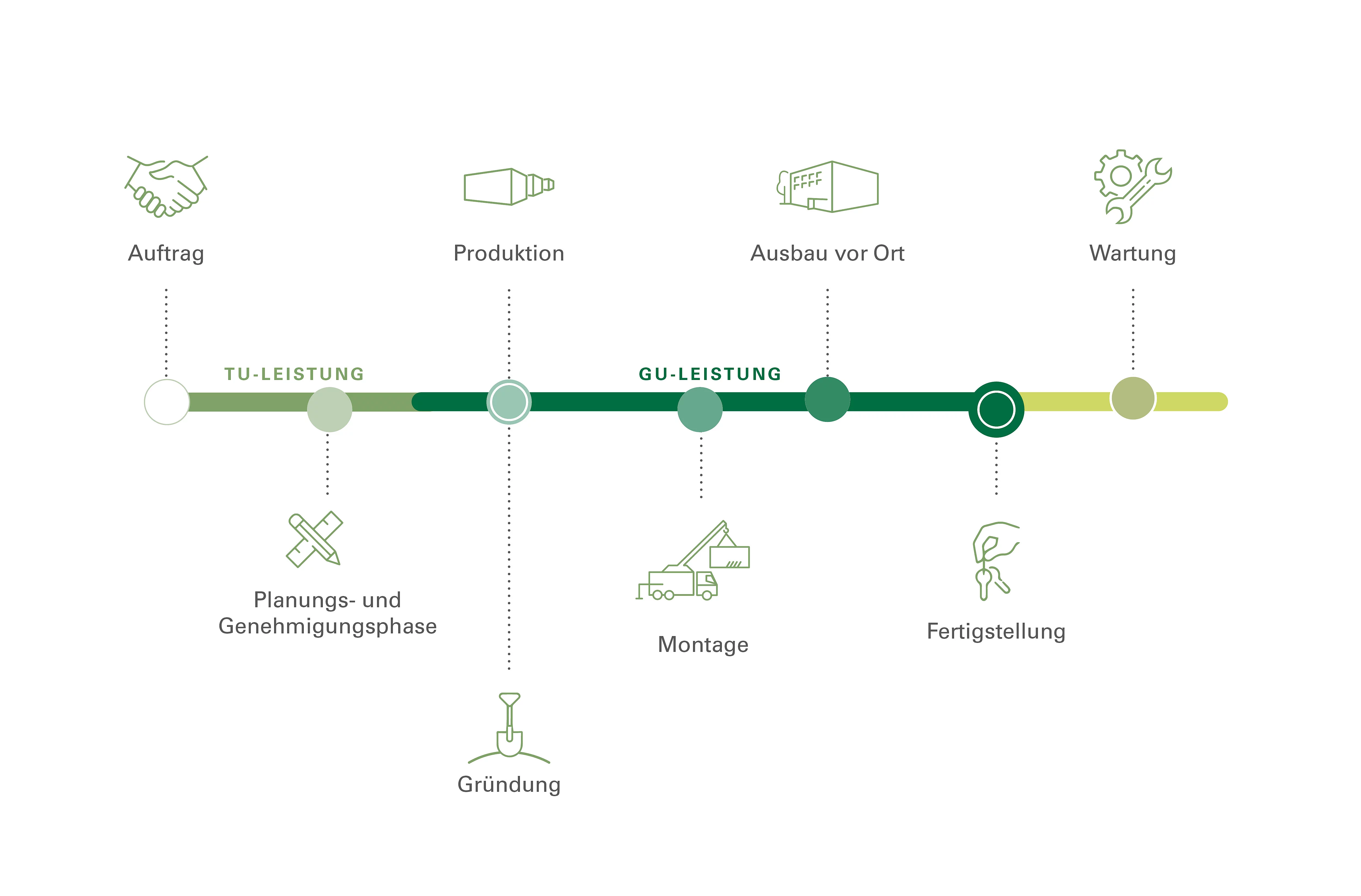

Project sequence in modular construction

As the project process in modular construction differs from that in conventional construction, a client who wants to realise his building project in modular construction turns to a general contractor for modular construction. ALHO also acts as a general contractor for its customers. This means that we provide all construction services for the erection of a building. We construct the building on a turnkey basis. We outsource individual (partial) services to subcontractors.

However, this does not alter the fact that ALHO, as the general contractor, is the client's sole contractual partner and bears full responsibility for the overall service. At the customer's request, we also offer planning services. If additional planning services are taken on, ALHO acts as total contractor. Further questions about the project process in modular construction are answered below.

In modular construction, the buildings are up to 70% prefabricated as ready-to-install modules in the factory and then transported to the construction site. The clean and quiet assembly of the modules usually only takes a few days. The connections between the modules must then be created and the roof and façade installed. The construction time on site - module assembly and finishing - is reduced to an average of 10 to 14 weeks, which is a considerable advantage, especially on inner-city construction sites and when building in existing buildings, as dirt and noise pollution are reduced to a minimum.

The modular grid enables fast and efficient planning. System reports, type statics and proven detailed solutions speed up the approval process and implementation planning. In serial production with standardised processes, we achieve a high degree of prefabrication and can build all year round regardless of the weather. The high degree of prefabrication of the modules in turn enables the extremely short construction time on site. All in all, the construction process is reduced by around 70% compared to conventional construction methods.

In principle, it is possible to convert almost any design into a modular grid and thus make it suitable for modular construction. However, small adjustments may be necessary afterwards. The design planning can therefore be carried out by an external architect commissioned by the client. Often, the design planning already exists before modular construction is discussed as an alternative. In this case, it is important to work together to find a grid that takes equal account of aesthetic, economic and technical requirements.

Ideally, however, the decision in favour of modular construction is made right from the start, so that the external architect and modular construction manufacturer can work hand in hand at a relatively early stage of planning. This offers planners the opportunity to familiarise themselves with and exploit the principles of modular construction.

If no design planning exists yet and the client does not have an architect at hand, our internal architects will be happy to take over the design planning or we can recommend a partner architecture firm specialising in modular construction.

We either support the architect commissioned by the client with the approval planning by providing all system-relevant documents, or we take over the approval planning for our customers. Both options are possible and are practised on a daily basis. Thanks to system reports, type-tested structural analyses and proven standard details of modular construction, the approval process is significantly simplified and accelerated.

The modules are produced in the ALHO room factory under consistently optimal conditions, regardless of the weather. The production process is subject to constant quality controls. Qualified specialist staff and subcontractors with many years of training are further guarantees of quality. In addition, we only use quality-tested branded products from German manufacturers. This certified serial factory production achieves a higher quality standard than is possible with conventional construction methods.

Modular construction is an industrialised form of building. A large part of the construction process takes place in the production hall, where the modules leave with a degree of prefabrication of up to 90 %. This means that only a small part of the construction process actually takes place on site. The construction time on site is usually only around 10 to 12 weeks, from module assembly to the finishing of the interior fittings and the façade. Noise and dirt pollution on the construction site is reduced to a minimum. The modular construction method is therefore also particularly suitable for building in existing buildings, where operations can continue without being affected by construction noise or dirt.

In modular construction, an external architect can provide service phases 1 to 4. From phase 5, the implementation planning, the modular construction specialist takes over. Many architects now appreciate having a strong partner at their side in the form of modular construction experts after the design and approval planning stage. Where necessary, they are relieved of the subsequent, often rather stereotypical stages of construction, such as work and detail planning, time-consuming tenders or so-called "dirty" phases such as site supervision.

Although such a concentration on service phases 1 to 4 does not correspond to the familiar, traditional service profile of an architect, it does offer the advantage of being able to accept new orders more quickly with a modular construction partner as general contractor and to focus on the service phases that are most financially rewarding - namely the design.

Your question has not yet been answered?

Please contact us!

Costs in ALHO modular construction

The costs for the construction of a modular building are comparable to those of a conventionally constructed building or are even cheaper in some cases. However, thanks to weather-independent production in the room factory, ALHO can build all year round and thus complete the building up to 70 % faster. On the one hand, this means that the financing period can be shortened accordingly, and shorter financing periods have a positive effect on the interest incurred. On the other hand, the properties can be put into operation and let more quickly, thus generating income sooner. In addition, modular construction stands for quality thanks to its certified processes and constant controls. Considering that the "number one cost driver" in construction is defects and their rectification, modular construction simply offers investors security - technically, in terms of time and financially.

The cost-effectiveness of modular construction lies in the serial production of recurring, consistent units. Engineering costs are incurred for the "set-up" of such a series, which can vary slightly depending on the complexity of the project. As a result, the realisation of a building in modular construction only becomes economically interesting with a certain number of units and a corresponding gross floor area. As a reference value, a minimum size of approx. 500 square metres of gross floor area (GFA) can be assumed.

Modular buildings have advantages over conventional buildings in terms of sustainability and life cycle costs. An LCC analysis determines the total costs that a building incurs over the course of its entire life cycle. Overall, the ALHO modular construction method generates 12% lower life cycle costs over the entire life cycle than conventional construction methods. This has been proven by studies carried out by a recognised certification office on the basis of several completed projects.

The ALHO building system with its self-supporting steel skeleton structure and non-load-bearing walls offers the possibility of adapting the modular buildings very flexibly to changing requirements. Walls can be moved or opened, and extensions and additions can be added at any time and in the shortest possible time. In this respect, the modular construction system is extremely flexible and very suitable for subsequent changes and conversions.

A major advantage of the ALHO modular construction method is the three-dimensional construction of the individual modules and the possibility of mechanically connecting them to each other - and also separating them again. These factors lead to cost-effective dismantling or disassembly and reassembly of the building ("mobile property"). Furthermore, the structural elements of a module can be 100% recycled and thus make a positive contribution to the recycling and reutilisation of building materials.

Your question has not yet been answered?

Please contact us!